Straight line edging machine reconditioning example

1. Removing front/rear conveyors

2. Cleaning internal guides and rails. Lubrication of gears and mechanisms

3. changing chains if necessary

4. Replacement of rubber and plastic rawplugs and mounting on the chain

5. Conveyors replacement inside of the machine

6.Painting after removing the casing and the various components. Re-assembling

6. Removal and replacement of caps (brushes, headphones, bellows).

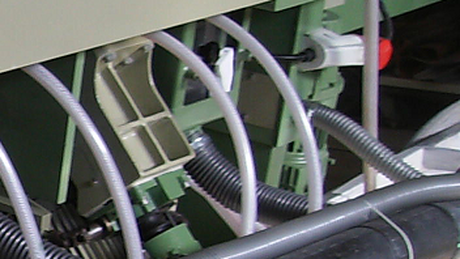

Replacing the rear tubes for water circuit

7.Removing and control of the spindles/worn bearings. Painting and replacement

8. Cleaning drawers of the wheels and replacing the seals

9. Getting work the machine and testing it

carters

RECONDITIONED